Testing.......Testing........ Why test knives? If you are a maker, what better way to check the quality of your product, and the progression of your skills? If you are a knife enthusiast, what better way to evaluate a product that you have laid down your hard earned cash to possess?

Testing can take on many different facets, from simply using a blade on a daily basis for the customer, to a much more intense, destructive method for the maker. I strongly believe that any blade intended as a "user", should be tested, as a quality control measure, prior to leaving the maker's shop. I personally utilize the "brass rod" test on all blades before delivery. This is a very simple test, first show to me by ABS Master Smith, Wayne Goddard. I have a very high regard for Mr. Goddard, and when he talks, I listen! Over the years since being introduced to this method of testing, I have come to realize that with it, one can determine the proper "working hardness" for almost any steel that I would consider worthy of a blade.

The test is conducted as follows:

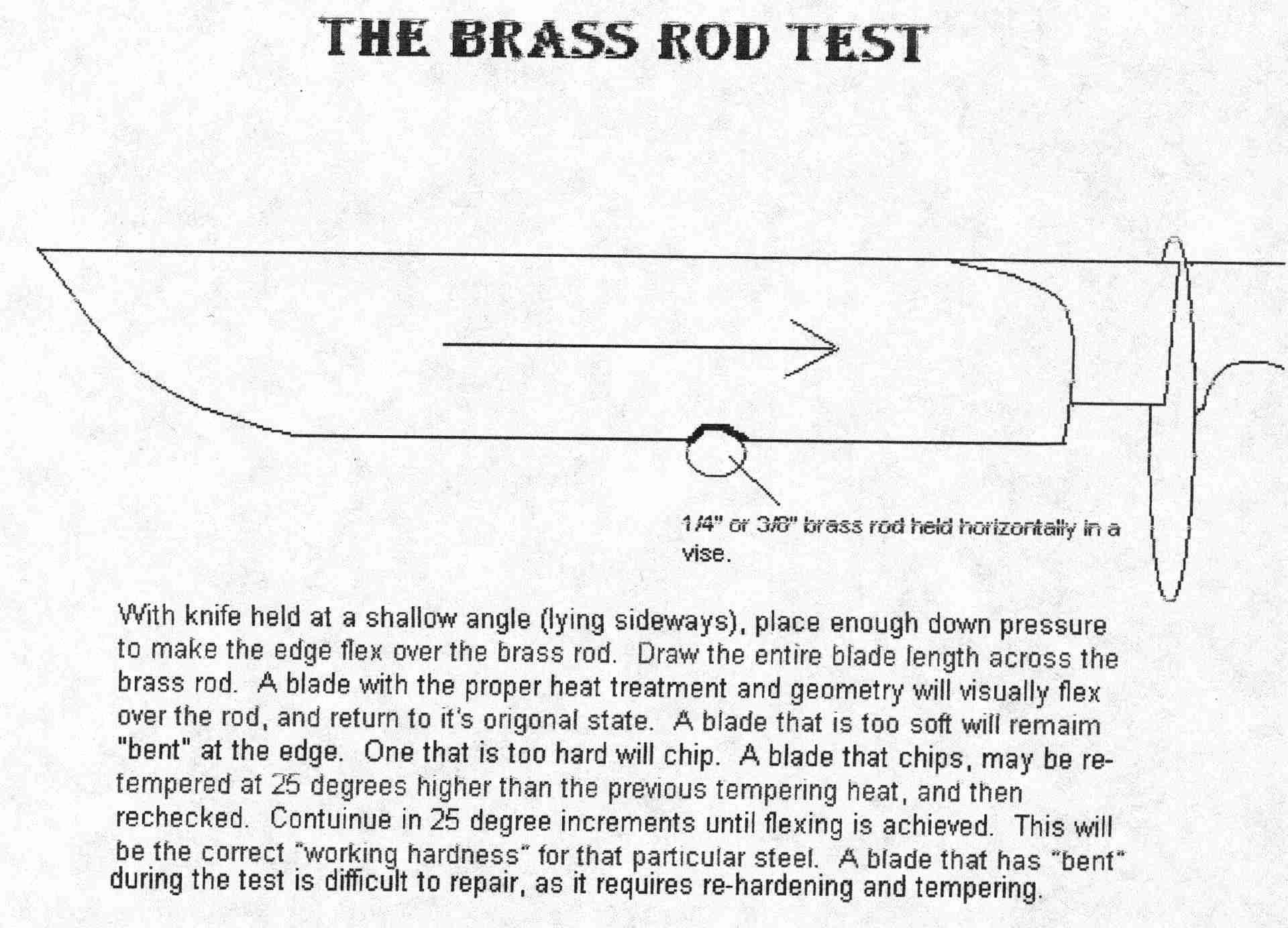

Place a length of 1/4" brass rod horizontally in a vise, leaving a few inches outside of the vise jaws. Starting near the ricasso of the blade/knife to be tested, and holding the blade at a shallow angle (approx. 20-40 degrees, depending on the grind), exert enough downward pressure to deflect the blade's edge over the brass rod. Draw the entire edge of the blade across the rod, while maintaining the pressure required to "flex" the edge. A blade that is the correct working hardness for that steel will flex over the rod, and return to it's original state. An edge that is too soft will remain flexed (bent/rolled), while one that is too hard will produce tiny chips along the edge. (At the bottom of this page is an illustration of the test) Should a test blade's edge be too hard (chipped during the test) it can be re-tempered at 25 degrees higher than previous tempering temp, and tested again, this process can be continued until the edge passes the test. A blade who's edge remains flexed (bent) is a bit more difficult to deal with, as the blade will require re-hardening and tempering. This is possible with some steels, while others may not tolerate it due to grain growth, or some other factor(s).

Another value of testing for the maker is the confidence that it builds. As I think back to my beginnings in the knifemaking arena, I can think of no other aspect that improved the quality of my knives more, than when I started seriously testing my work, and using the results to form theories. The rest was simply a matter of experimenting to either prove or disprove those theories. From this came my current methods of forging, grinding, and heat treating.

The types of tests used by each individual is totally up to them. Some suggestions that I would offer would be to make things as equal as possible. Use the same materials and techniques to test each blade. Be realistic, use tests that will closely resemble day to day tasks that would be expected of a given knife. I have been amused at advertisements stating that a blade was stabbed through a 55 gallon drum, or a car door X number of times, and sustained no damage. I can do this with a crowbar, why would I want to do it with a knife? There are, of course, situations that MAY call for a blade to endure this type of treatment such a military operations, or a survival situation, but the average knife user will likely never encounter this need.

Think of the types of chores that you would most likely do with your blades and start there. Cut some cardboard, cut some rope, whittle on a few sticks. As time goes by you will develop your own set of standards and tests.

As for me, I used the brass rod test on nearly every single blade. I also cut hemp rope, and chop boards and limbs with camping sized blades. Every now and then I will destroy a blade, just to ensure that quality is not slipping.

In conclusion, I can think of no better way for a maker or customer to gain knowledge and confidence in a product than to test and evaluate that product. We do it everyday of our lives with foods, household items, and automobiles, why not with our knives?

Testing can take on many different facets, from simply using a blade on a daily basis for the customer, to a much more intense, destructive method for the maker. I strongly believe that any blade intended as a "user", should be tested, as a quality control measure, prior to leaving the maker's shop. I personally utilize the "brass rod" test on all blades before delivery. This is a very simple test, first show to me by ABS Master Smith, Wayne Goddard. I have a very high regard for Mr. Goddard, and when he talks, I listen! Over the years since being introduced to this method of testing, I have come to realize that with it, one can determine the proper "working hardness" for almost any steel that I would consider worthy of a blade.

The test is conducted as follows:

Place a length of 1/4" brass rod horizontally in a vise, leaving a few inches outside of the vise jaws. Starting near the ricasso of the blade/knife to be tested, and holding the blade at a shallow angle (approx. 20-40 degrees, depending on the grind), exert enough downward pressure to deflect the blade's edge over the brass rod. Draw the entire edge of the blade across the rod, while maintaining the pressure required to "flex" the edge. A blade that is the correct working hardness for that steel will flex over the rod, and return to it's original state. An edge that is too soft will remain flexed (bent/rolled), while one that is too hard will produce tiny chips along the edge. (At the bottom of this page is an illustration of the test) Should a test blade's edge be too hard (chipped during the test) it can be re-tempered at 25 degrees higher than previous tempering temp, and tested again, this process can be continued until the edge passes the test. A blade who's edge remains flexed (bent) is a bit more difficult to deal with, as the blade will require re-hardening and tempering. This is possible with some steels, while others may not tolerate it due to grain growth, or some other factor(s).

Another value of testing for the maker is the confidence that it builds. As I think back to my beginnings in the knifemaking arena, I can think of no other aspect that improved the quality of my knives more, than when I started seriously testing my work, and using the results to form theories. The rest was simply a matter of experimenting to either prove or disprove those theories. From this came my current methods of forging, grinding, and heat treating.

The types of tests used by each individual is totally up to them. Some suggestions that I would offer would be to make things as equal as possible. Use the same materials and techniques to test each blade. Be realistic, use tests that will closely resemble day to day tasks that would be expected of a given knife. I have been amused at advertisements stating that a blade was stabbed through a 55 gallon drum, or a car door X number of times, and sustained no damage. I can do this with a crowbar, why would I want to do it with a knife? There are, of course, situations that MAY call for a blade to endure this type of treatment such a military operations, or a survival situation, but the average knife user will likely never encounter this need.

Think of the types of chores that you would most likely do with your blades and start there. Cut some cardboard, cut some rope, whittle on a few sticks. As time goes by you will develop your own set of standards and tests.

As for me, I used the brass rod test on nearly every single blade. I also cut hemp rope, and chop boards and limbs with camping sized blades. Every now and then I will destroy a blade, just to ensure that quality is not slipping.

In conclusion, I can think of no better way for a maker or customer to gain knowledge and confidence in a product than to test and evaluate that product. We do it everyday of our lives with foods, household items, and automobiles, why not with our knives?

Knife Testing

"Nobody Cares What you Know...

Until They Know You Care!"

Until They Know You Care!"

Copyright 2024/25: "The Montana Bladesmith"

406-727-9102